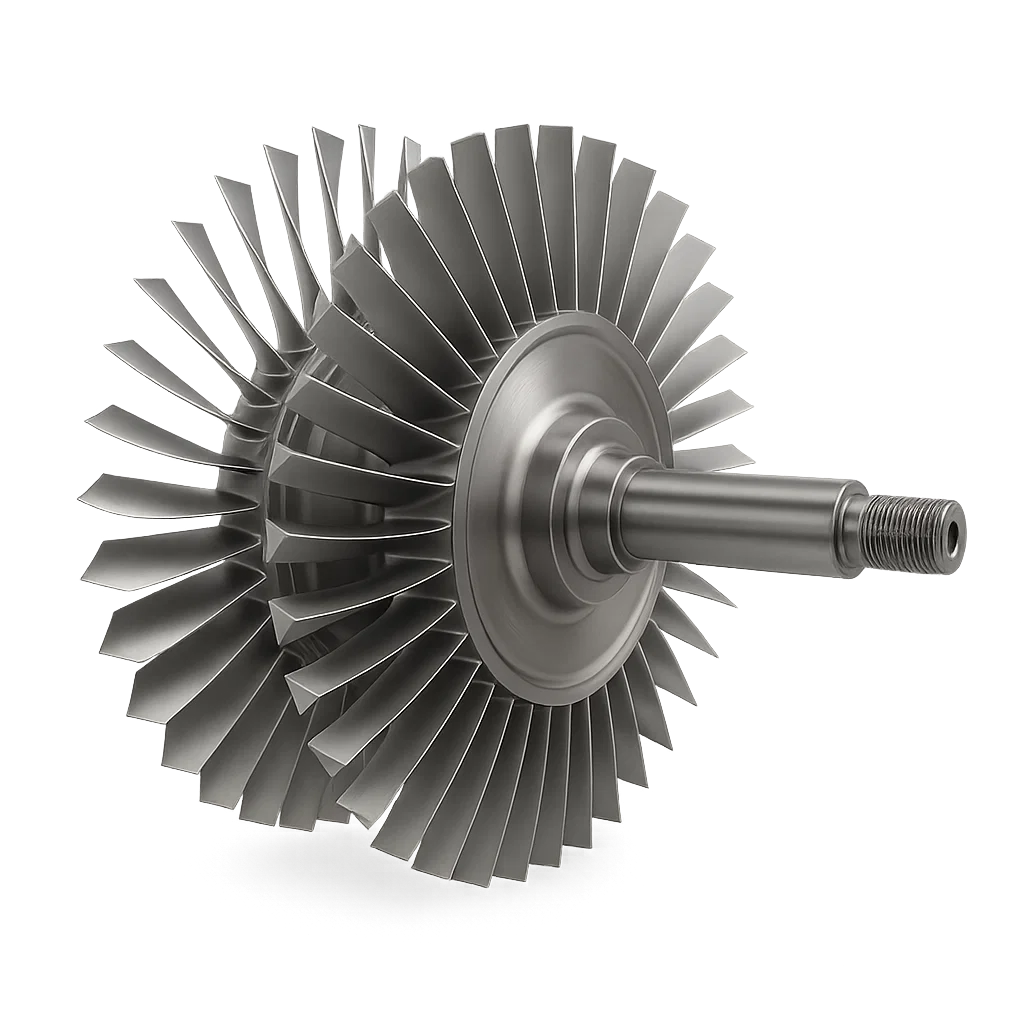

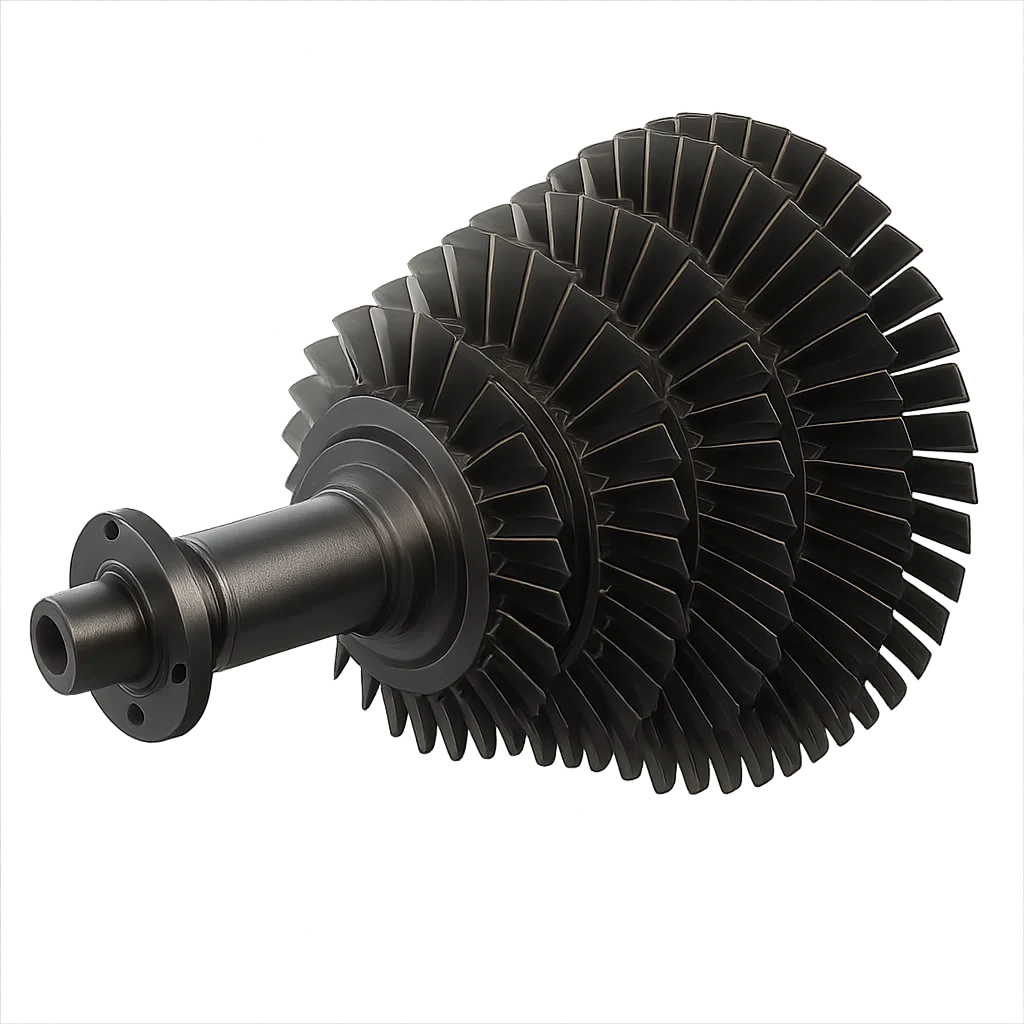

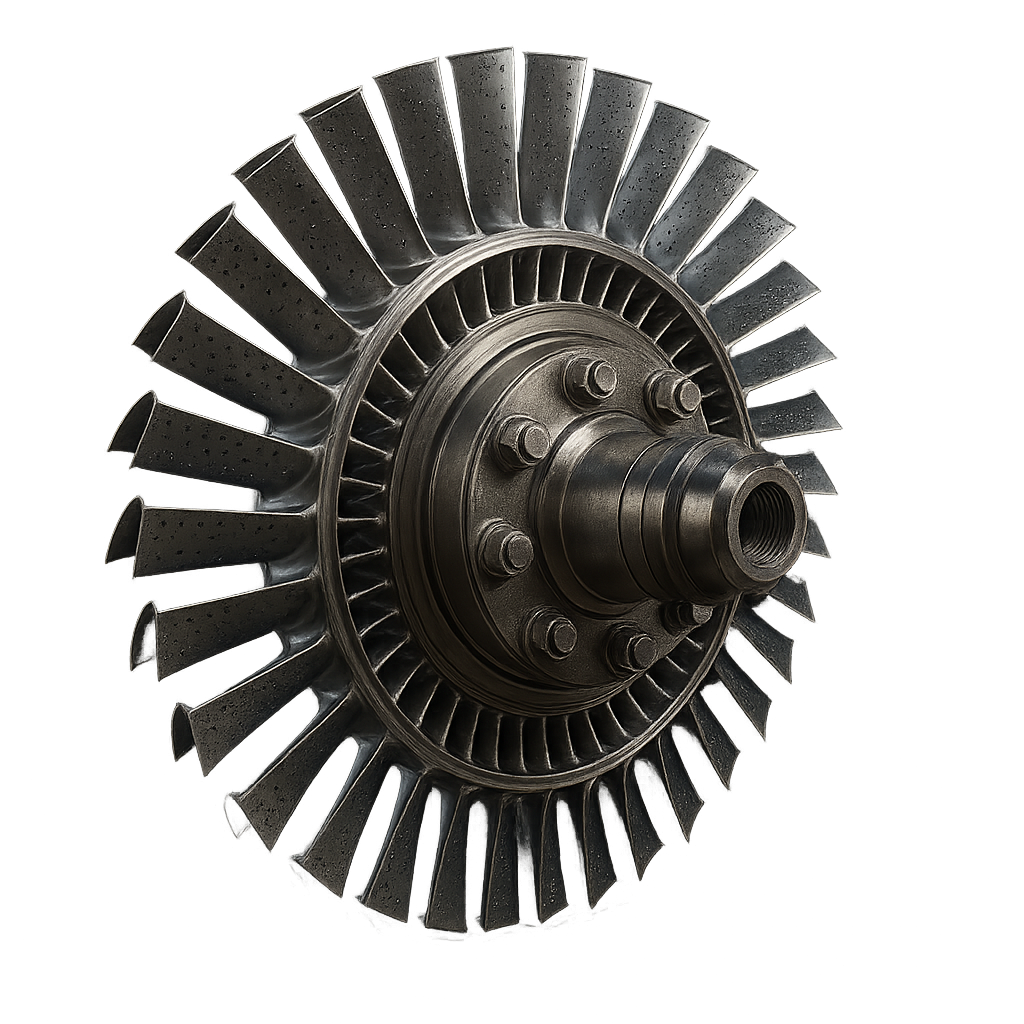

Technical Specifications

- Engine Type: Twin-spool, low-bypass adaptive turbofan

- Maximum Thrust: 160 kN (with afterburner)

- Bypass Ratio: 0.7:1 (Combat) to 3.5:1 (Cruise)

- Core Materials: CMC, Inconel 718, Ti-6Al-4V

- Overall Length: 4.25 m

- Dry Weight: 1,950 kg