1. Executive Summary

The Xena XF-1200 is a next-generation adaptive turbofan engine featuring twin-spool architecture and variable bypass technology, optimized for both civil and military applications. Designed with ultra-high efficiency materials, hybrid architecture, and variable-cycle capability, it enables seamless transitions between high-power combat operations, fuel-efficient cruise flight, and reduced thermal signature modes. The engine is specifically engineered to power future platforms with a focus on performance, sustainability, and tactical survivability.

2. Design Definition File (DDF)

Official Designation:

Xena XF-1200

Engine Type:

Twin-spool, low-bypass adaptive turbofan with hybrid electric booster

Stage Configuration:

- Fan: 1 stage (with reduction gearbox)

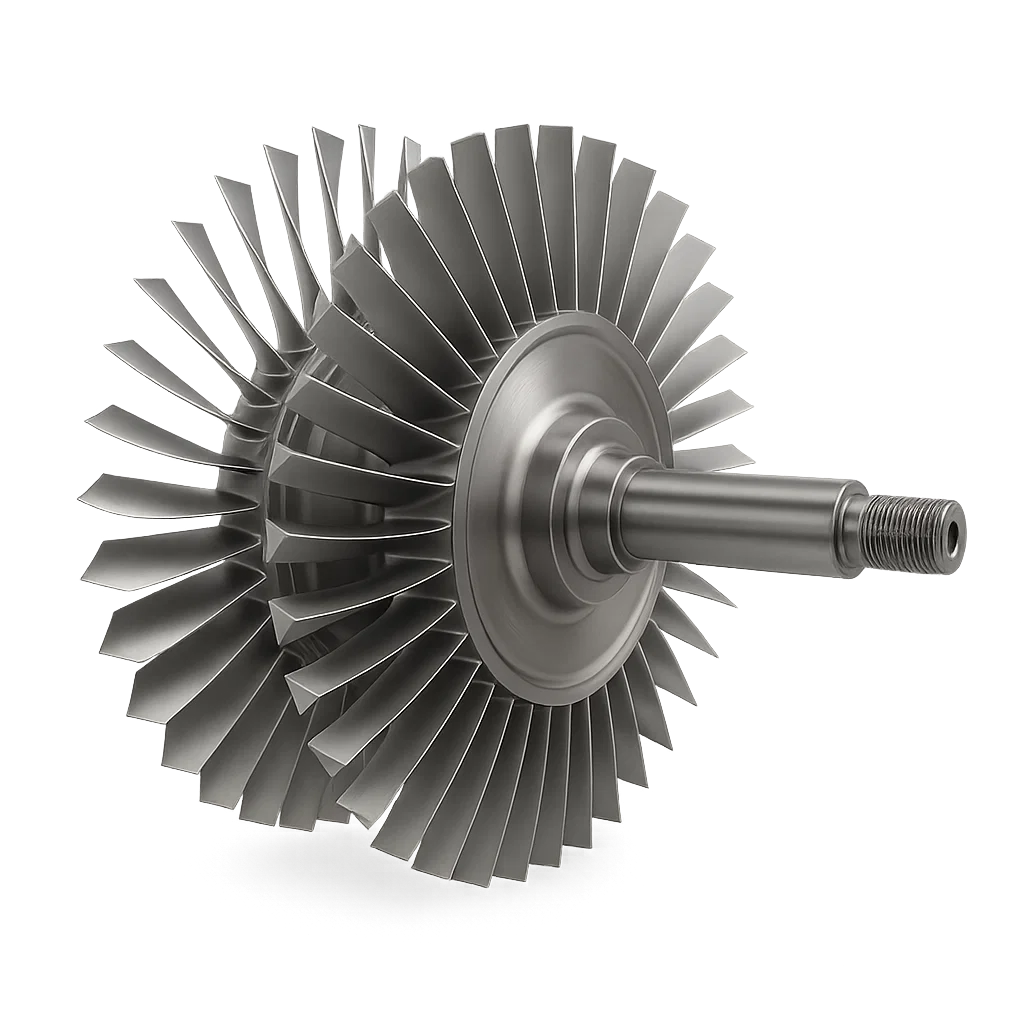

- LP Compressor: 3 stages

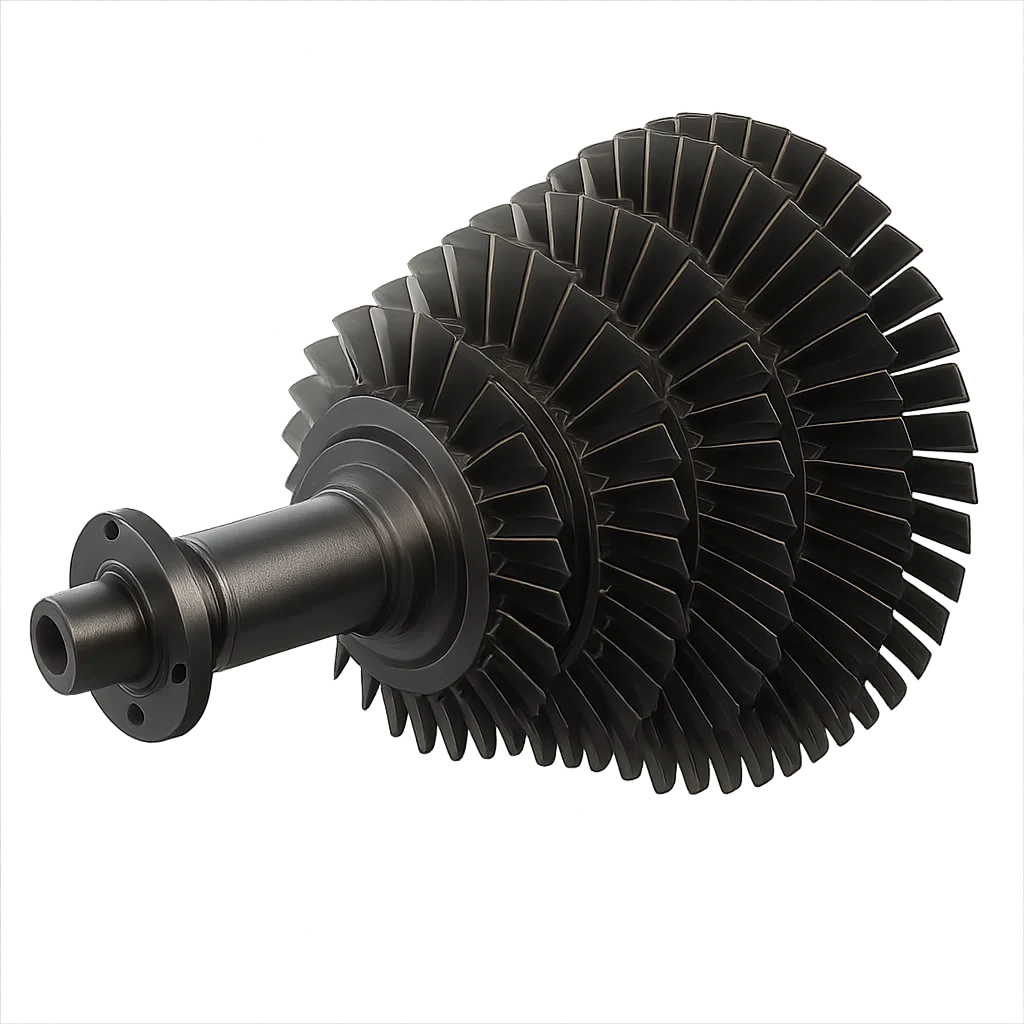

- HP Compressor: 8 stages

- Combustion: Annular, dual-flow, plasma ignition

- HP Turbine: 2 stages

- LP Turbine: 2 stages

- Booster Shaft: 1 (integrated electric motor)

Bypass Ratio (Adaptive):

0.7:1 (sprint mode) → 3.5:1 (cruise mode)

Thrust Rating:

Dry Thrust: 92 kN

Afterburning/Maximum: 160 kN

Dimensions and Weight:

Overall Length: 4.25 m

Maximum Diameter: 1.15 m

Dry Weight: 1,950 kg

3. Preliminary Bill of Materials (BOM)

| Module | Primary Material | Manufacturing Process |

|---|---|---|

| Fan | CMC (Ceramic Matrix Composite) | 3D Printing + CNC machining |

| LP Compressor | Ti-6Al-4V + CMC | Machining + AM cooling channels |

| HP Compressor | Inconel 718 + Ti blades | Forging + thermal coating |

| Combustion Chamber | Hastelloy-X alloy | Welding + laser internal polishing |

| Turbines | Ni-based single crystal alloys | Directional solidification casting |

| Concentric Shafts | Tempered steel + coating | Rolling + heat treatment |

| External Casing | Carbon fiber + RAM coating | Infusion + sectional assembly |

| Electric Booster | Copper windings + CMC housing | Metal printing + varnishing |

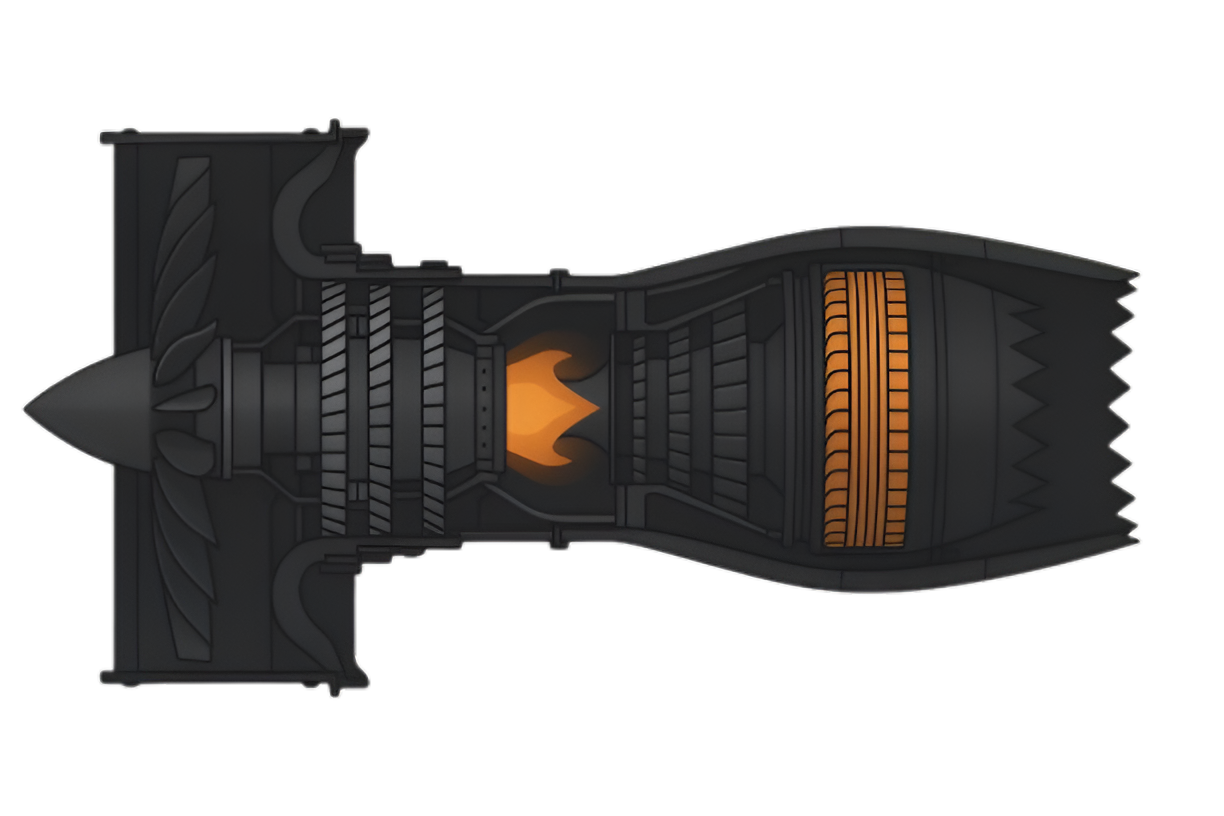

4. Cross-Section Diagram and Components

Primary Modules

5. Variable-Cycle System (Adaptive)

The core innovation of the XF-1200 lies in its ability to actively alter its bypass ratio during operation. This is achieved through a series of variable inlet guide vanes and a controlled third stream airflow, allowing the engine to reconfigure in real-time according to flight phase requirements. Switching is accomplished via high-speed magnetic actuators, governed by a predictive control algorithm with optional AI assistance.

| Operating Mode | Bypass Ratio | Tactical/Operational Advantage |

|---|---|---|

| Sprint / Combat | 0.7:1 | Maximum speed and thrust for interception or escape maneuvers. |

| Cruise / Loiter | 2.5–3.5:1 | Maximum fuel efficiency, extending range and endurance. |

| Stealth / Infiltration | 1.8:1 | Optimal balance for reducing thermal, acoustic, and IR signatures. |

6. Performance Analysis

Operational Envelope:

The XF-1200 is designed to operate efficiently across a wide range of flight conditions, from sea level to 65,000 feet altitude, and from subsonic cruise to supersonic combat speeds exceeding Mach 2.5.

Fuel Efficiency:

In cruise mode, the engine achieves specific fuel consumption rates 15% lower than current generation engines, while maintaining superior thrust-to-weight ratios across all operating conditions.

Environmental Impact:

Advanced combustion technology and optimized cycle parameters result in NOx emissions 40% below current regulatory limits, with CO2 emissions reduced through improved thermal efficiency.

7. Development Roadmap (TRL)

| Phase | Target Date | Expected Outcome |

|---|---|---|

| Conceptual Design | ✅ June 2025 | Complete technical dossier |

| 3D CAD Design | July - September 2025 | CFD + FEA simulations |

| Virtual Test Bench | October 2025 | Integrated simulation testing |

| TRL 5 Prototype | December 2025 | Operational fan + hybrid shaft |

| TRL 6-7 | 2026 | Full combustion testing |

| TRL 8-9 | 2027 | EASA/FAA certification |